Duct Manufacturing & Production Process

-

01 CNC Input, Seam joining and Cleat bending

- After receiving the tagged drawing a fabrication schedule is prepared for the ducts to be made after coordinating with the customer

- The fabricator receives the fabrication schedule and dimensions of the duct to be manufactured

- CNC Operator inputs the data into the CNC machine such as coil line or Plasma cutter

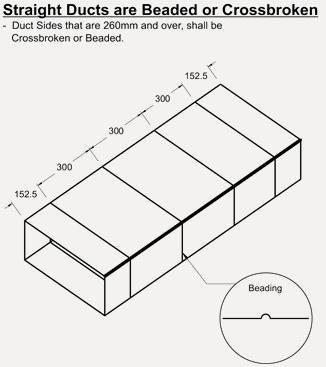

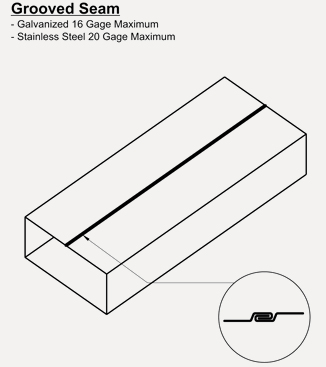

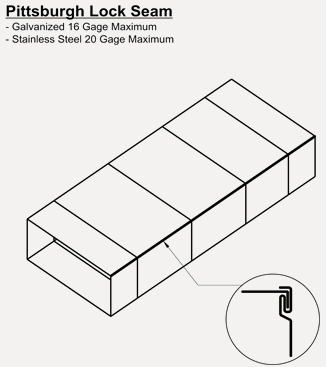

- The square ducts are processed through the CNC operated Coil Line machine to make ducts of 1200mm (standard length). This duct is then passed through the duct zipper for seam joining and Automatic Precision Cleat bending machine for “C” cleats to form complete duct. At each stage, a factory foreman is continuously monitoring the quality. After completion these ducts are sent to quality inspection by Quality Assurance Department.

-

02 Plasma Cutting

- The Duct fitting are processed through the CNC controlled Plasma Cutting System. The fabricator feeds the data in the system and the system automatically nests the parts on the sheets with the precise measurements. The Plasma Cutting tables are then loaded with GI steel and the fitting parts are cut. The fabricator identifies the pieces with the help of layouts prints and marks the dimension along with fabrication instructions that deal with bending, rolling, etc.

-

03 Lock- forming, rolling, bending, flanging, spot welding and cleat bending

- After beading the parts are passed through various processes such as lock- forming, rolling, bending, flanging, spot welding and cleat bending as per the requirement of the fitting. The fitting parts are then moved to the assembling section, where the parts are assembled, while it’s add on flange are fixed, stiffness for large ducts are added etc. The factory foreman monitors all the processes so as to ensure the highest quality of products

-

04 Quality Check

- Multiline Industries delivers quality products by strictly following high level of quality checks during the production process. From procurement of raw materials to the final stage of production, each step is monitored by expert professionals.

- Multiline Industries delivers quality products by strictly following high level of quality checks during the production process. From procurement of raw materials to the final stage of production, each step is monitored by expert professionals.